ISTblast Wet Blast Systems

Pacific Spray Booths is a distributor of ISTblast wet blast systems. Built with strong stainless steel, they offer advanced features to ensure efficient operation, operator comfort, maximum cleaning as well as good visibility and ease of use. As with dry blasting cabinets, similar work piece handling options can be integrated to automate the process.

In wet blasting, a water-abrasive mixture is used resulting in smoother finish and less dust inside cabinet. Water washes away contaminants like grease and oil. In dry blasting these contaminants could cause coagulation of the abrasive and lead to machine failure. That is why wet blasting is often used for refurbishing parts such as motor and compressor parts. As with other Industrial M Series Sandblasting Cabinets, wet blast systems can be pressure or suction.

Pressure-Fed Wet Blast Cabinets

Pressure-fed wet blast cabinets are designed specifically for production applications where high work output is required, combined with optimum abrasive quality.

Suction-Fed Wet Blast Cabinets

Suction-fed wet blast cabinets are designed specifically for production applications where less aggressive surface treatment is required, such as getting smooth surface finishing on different items. Suction-fed blasting is less powerful than pressure-fed blasting, but uses significantly less compressed air.

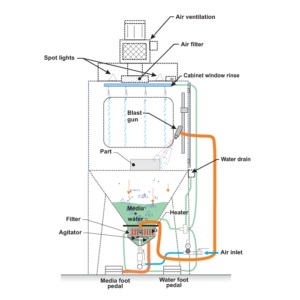

How It Works

Cabinet Features

- Stainless steel construction

- Large viewing window with water spray and wiper

- Integral turntable for easy component handling (Roll-in turntable option available)

- Adjustable gun holder

- Interlocked door

- Simple hands-free pump controls

- High performance wear-resistant pump and process gun

- Easily maintenance for pump and motor

- Can be used with wide range of abrasives, glass beads or soft blast grits

- Wide range of options including automation